Process Overview

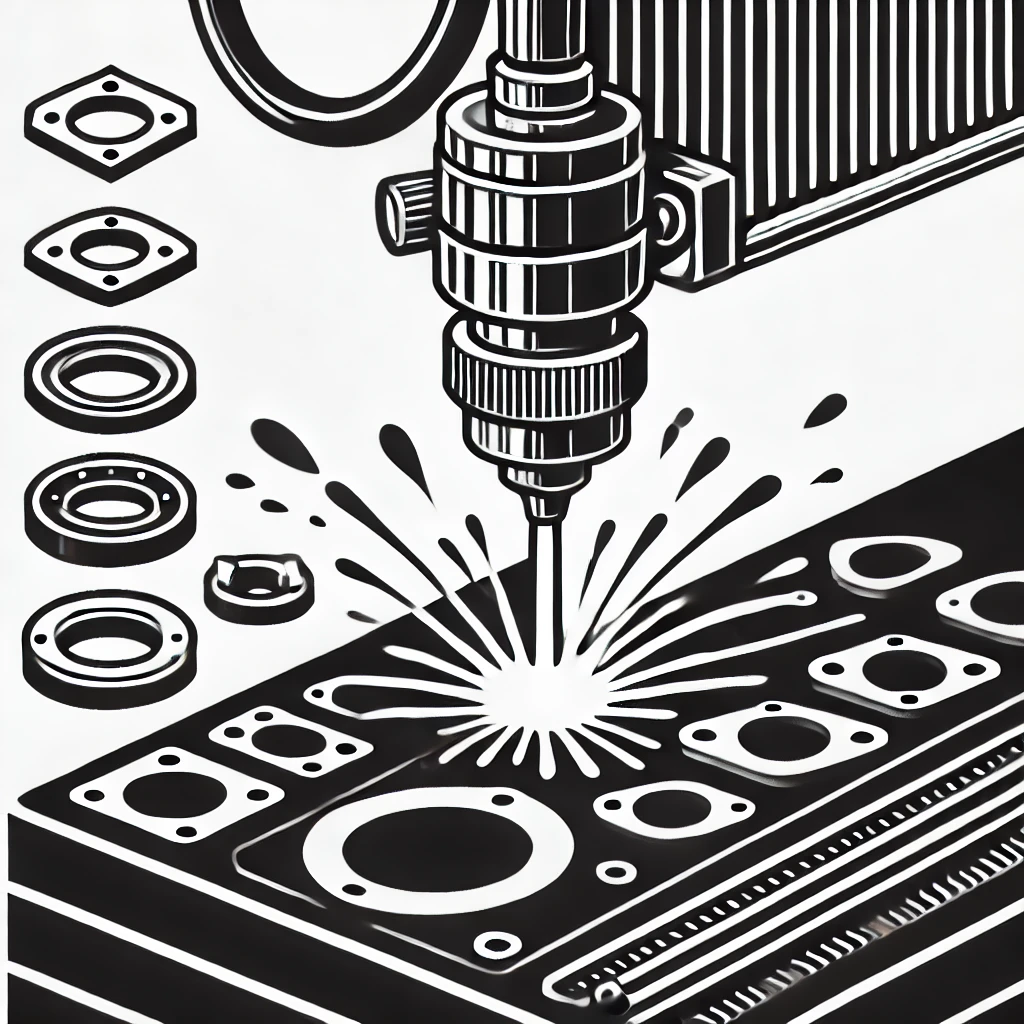

Water jet gasket cutting is a precise manufacturing process that uses a high-pressure water stream to cut through various gasket materials. This method allows for intricate shapes without thermal distortion, making it ideal for rubber, silicone, foam, and composites.

Benefits and Sustainability

It is environmentally friendly, generating minimal waste and requiring no harmful chemicals, while ensuring consistent quality and accuracy for customized gasket solutions.

We Are The Best in The Business

For the most precise custom water jet gasket cutting, look no further than Ilene Industries, Inc. We would be happy to provide you with a detailed quote and more information about our process.

Laser Precision

Water jet cutting technology provides laser accuracy, surpassing older and outdated gasket cutting methods. This precision allows for intricate cuts with clean edges, ensuring top-quality results every time.

Extremely Efficient

Water jet gasket cutting is not only precise but also quick. The process helps speed up production, allowing for faster turnaround times without compromising on quality.to perfection.

Reliable

This technology is highly reliable, consistently delivering impressive results. It ensures the same high standards across multiple cuts, making it a trusted solution for gasket cutting needs.

Capabilities:

Thickness: Cuts thicknesses up to 4”

Sheet Size: Cutting up to a 4′ x 8′ sheet of material

Abrasive Jet Cutting Advantages

Jet Edge abrasive jet cutting systems use a combination of water and garnet to cut through materials considered “nonmachinable” by conventional cutting methods.

- No Thermal Damage: Abrasive Jet cutting avoids thermal damage that can negatively affect the metallurgic properties of materials.

- Complex Shapes: It is excellent for cutting complex shapes, and for fragile materials like glass, the high failure rate due to breakage is virtually eliminated.

Water Jet Cutting Advantages

Waterjet cutting uses a powerful jet of water that cuts through materials cleanly and precisely in a single pass without shredding or crushing. When coupled with a suitable motion control system, waterjet cutting provides highly accurate cuts with a high degree of repeatability over a wide range of materials and shapes.

Materials commonly cut with waterjet

TECHNOLOGY INCLUDES:

✓ Plastics

✓ Metal (all types)

✓ Non-Woven Materials

✓ Insulation

✓ Sponge / Foam

✓ Paper / Vegetable Fibers

✓ Rubber

✓ Ceramic & More